MSR Houston Debrief-

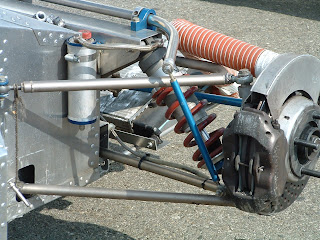

New front suspension, new drivetrain, an untested IRS with nylon composite springs and control arms, I haven’t been wheel-to-wheel under race conditions in over 12 years, and it’s supposed to rain on and off all weekend. What could possibly go wrong? Here’s a blow-by-blow:

Unrelated – the AC compressor in the truck froze up on the trip down. Fortunately I caught it before it ate the serpentine belt, but it set the hot and muggy tone for all that was to come.

First and foremost – can’t say enough about the people down there in Houston. While my SCCA experience has always been family-like, these people went out of their way to accommodate me and to help me with any and all problems. Southern hospitality at it’s finest. A shout out to Matt Blehm and Larry Svaton for making it a point to introduce themselves first thing and offer any help possible.

Friday practice – boy is MSR Houston a bumpy track – the roughest I’ve ever been on! While I set the car up with extra ground clearance, my spring rates were definitely too high, with no tuneability other than shocks at this point. Damping seemed okay, so I focused on learning the track. Got in 3 or 4 laps, seemed like the engine was a little flat. All of a sudden, engine wouldn’t rev past 3k, pulled it in. Looked at the data logs, AF ratio was at 14.7 and steady, so the EMS said no more revs. Turns put I’m not getting any Lambda feedback. Called AEM support, thinking I had a software or setup problem, they said test the O2 sensor first. Went to disconnect the sensor and “aha!” – two of the pins had come loose from the connector block. A little rewire and everything working well.

Friday night – car was tuned on 104 octane, turns out the oxygenated unleaded fuel I used wasn’t going to pass a fuel test. Switch to 100 octane track gas, take out a little timing, hope for the best.

Saturday AM practice – Skipped due to rain, want to save the car and make sure I qualify!

Saturday Qualifying - Just want to take a couple hot laps, get a qualifying time, and then check the data logs to make sure there’s no detonation. Notice a misfire or “burble” around 4000-5000 rpm on the out lap, but it cleans up and runs fine above that. Attribute that to the timing change. First hot lap, misfire is still there but manageable, about halfway through lap one, lose all electrical power! First test of the front tow strap goes well. Get to the pits and get out the testlight. No power at the shutoff switch. Rookie mistake! Loose battery terminal has popped off. Easy fix, but no qualifying time. Talk to Chief Steward, more than happy to grid me for the race regardless. Phew!

Saturday Race – out lap is good, misfire still there, otherwise fine. Race lap 1 – following two cars behind Larry Svaton (GTL in 1st place), go to pass underneath the car in front, realize I’m too deep too early, brake hard, pedal feels funny, a bit wooden, but car slows okay, turn-in, and spin it. Didn’t think I was going in that hot, and didn’t expect it, but oh well. Stayed on track, straightened out, under way. Pedal feels okay next few corners, time to boogie! Completed my first official race lap in 12 years! Also, first race lap ever in the world (we believe) for a car with thermoplastic springs. Did we just make a little history? Who knows… Lap 2, watching my lines, brake for a turn, exit okay, going down on power, misfire? Front brakes are locked, manage to get to the inside off-track, pedal is frozen at the top, won’t release. End of race, out comes the flatbed, hauls me up backwards which releases the brakes (and confirms the rear tow hook works well also), and into the pits.

Saturday night – I remember hearing the previous owner had had some brake issues, thought I had found them when I converted to Wilwoods in the rear. The rear master was corroded and frozen, so I replaced it months ago. Turns out the front master had the pushrod adjusted too tight, when things got hot the piston didn’t return far enough to open the relief hole. Rotors are smoked – Holly over in impound manages an O’Reilly’s, calls around, locates me a pair of rotors in Houston, so I’m going to miss the track dinner. Off I go, back in a few hours, put the new rotors on in the dark, then back to the hotel for some sleep.

Sunday AM – looks like rain all day. Flush and bleed front brake system, double check pushrod adjustments, pedal feels way better than it ever has. Put on the rain tires.

Sunday Qualifying – Raining pretty steady, have never raced in the rain, but excited to try. I’ve driven hard in a FWD car in the rain, and know what to expect. Except for the misfire, car runs great, I pass people and no one passes me, I log the second fastest time in the whole group! Feel great, come in, and pray for rain the rest of the day.

Sunday Race – Rain stops, track has dried, no more rain any time soon, switch to slicks. 5 minutes to grid. Suit up, strap in, hit the starter switch, a “pop” and a blue flash and the fuse blows. Jump out, run to the truck, open the fuse box, rob a fuse, get back in, stabbing the switch,starter clicks a few times but she finally goes. Get to grid, leave it idling sitting in the heat, watching the temp gauge, thankful that my radiator fan is working, and out we go. Feels good (except for the misfire), green flag, we’re racing! Pass the first HP car in front of me, watch the other GTL in third place get smaller in my mirror, feeling good, watching my lines, keeping Larry in my sights a few cars ahead. Start watching the B-Spec in front of me, figuring where to pass him. Pull up alongside on the back straight, but not quite ready for two wide in the sweeper, want to be clean and courteous. Tuck in and follow. Lap four, power goes down. Little misfire is now a big one, can’t even limp in. Pull off at the corner station. My weekend is done, but I’m feeling good. The rear suspension, which was the whole purpose for being here, never missed a beat. As rough as things were, it stayed hooked up. Balance was pretty good out of the box. All the other issues were minor ones, and I’m pretty sure the misfire issue is in the distributor. When I checked timing sync before I left for the races, it was a little erratic and I dismissed it as my timing light getting old (20 yrs or so). My misfire, and the cause of Sundays DNF, is likely the crank position sensor in the distributor. I’m pretty darn sure of that, and I’ll pop in the spare distributor (and a new starter) this week. If that’s the case, I’ll probably be in St. Louis in a few weeks! (New distributor did indeed fixed the problem, we'll be at Gateway Motorsports Park for the May 14-15 race).